11001 Pains of Factory Owners – The Untold Truth Behind Laundry Detergent OEM Production

In the manufacturing and OEM production of laundry detergent and cleaning products, there are pains only insiders truly understand. Many think the formula determines the product quality, but in reality, raw materials are the lifeline — especially key ingredients like SLES 70% and Glycerin 99.7%.

As a wholesale supplier of raw materials for cosmetics and cleaning product manufacturers, we have had the chance to work with — and “share the pain” of — hundreds of factory owners every year. Below is a summary of the most pressing issues that laundry detergent producers often face, and how to solve them at the root.

1. Unstable finished products despite unchanged formulas

Many factory owners have complained:

-

“Same formula, but today it’s runny like water…”

-

“Yesterday it took 10 minutes to mix, today 2 hours and still not dissolved…”

-

“The product separates or clumps right after bottling…”

The problem doesn’t lie in the process or formula. In 90% of cases, it comes from substandard raw materials:

-

SLES 70% with insufficient active matter, high impurities, and inconsistent quality from batch to batch.

-

Glycerin with purity lower than promised, diluted with water, contaminated with base odors, or unstable in color.

This results in loss of viscosity, water separation, inconsistent scent — all directly affecting user experience and brand reputation.

2. One ruined batch = millions lost, contracts gone

For small and medium-sized factories, a failed batch means:

-

Losing 3–5 million VND worth of raw materials.

-

Losing packaging and labor costs.

-

Wasting time and missing delivery deadlines.

-

Damaging credibility with clients, especially in OEM contracts.

Some factories even shared: “Trying to save 1 million on raw materials, but losing a whole 20-million batch means we end up with nothing.”

3. Every batch of raw materials is different – making formulas “useless”

When raw materials are inconsistent, even the most precise formula becomes meaningless. One batch of SLES may have high viscosity, the next one thin as water. One batch of glycerin is crystal clear, the next cloudy.

This causes every production run to differ:

-

Inconsistent foam levels.

-

Unstable thickness/viscosity.

-

Fragrances failing to mask base odors.

Customers will complain: “This batch isn’t like last time” — and this is why many small brands never grow, losing trust due to lack of consistency.

4. The root cause: substandard raw materials

Some suppliers, to save costs, buy unverified raw materials with unknown origin — lacking COA, MSDS, or independent testing. The consequences:

-

No control over the actual active matter content of SLES.

-

Glycerin diluted with water, leading to viscosity changes and shorter shelf life.

-

Hard to troubleshoot when technical issues occur.

5. The sustainable solution: choose the right quality materials

👉 SLES 70% that meets standards must:

-

Have ≥70% active matter.

-

Contain minimal impurities, free of heavy metal ions.

-

Have stable viscosity, clear color.

-

Come with full COA, MSDS — imported from reputable factories.

-

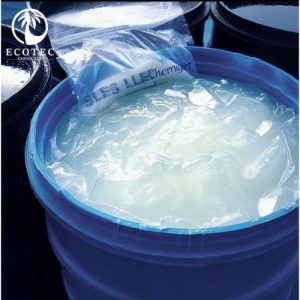

SLES 70%

👉 High-quality Glycerin 99.7%:

-

Pure, undiluted, odor-free.

-

Helps stabilize formulas, retains moisture.

-

Softens fabrics and is safe for users’ hands.

6. We don’t just sell – we partner with you

With experience supplying raw materials to hundreds of factories, we commit to:

-

Supplying technically compliant raw materials with complete documentation.

-

Providing free samples for formula testing before bulk orders.

-

Offering technical consultation and troubleshooting for mixing errors when needed.

-

Nationwide delivery – wholesale prices flexible by quantity.

Bạn đang gặp nỗi đau trong sản xuất nước giặt?

Are you facing pain points in laundry detergent production?

👉 Don’t hesitate to contact ECOTEC CHEMICALS for industrial-grade SLES 70% and Glycerin 99.7% samples.

👉 Let’s discuss, share, and optimize your production process effectively and economically.